|

1 2 3 4

Extraction Zone

Purification Zone

Cotrol Plane

Pressure Filter

|

Extraction Zone |

Purification Zone |

Cotrol Plane |

Pressure Filter |

Healthgen Biotech has two different pilot manufactories, one with an annual production capacity of 150kg OsrHSA and the other with 1000kg OsrHSA per year. The GMP compliance factory and advanced equipment enable Healthgen to produce high quality and good batch consistency OsrHSA.

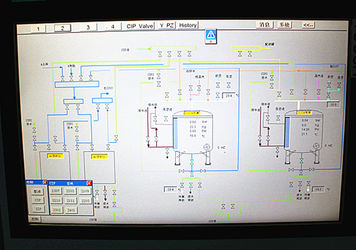

In the GMP compliance factory, there are 4 extraction tanks, which are 2500 liter each for the extraction process. So, we can feed 10 tons of material liquid maximum for each batch. The extraction buffer is from the preparation solution center on the second floor. The extraction processes are full-auto-control with auto valves and PLC (Programmable Logic Controller) control system. The materials are transferred by closed sanitary pipes, which can effectively reduce the risk of production, and also, this is favored by pharmaceutical companies around the world. After the extraction process, we use these two bedplate frame filter press filters, which are imported from PALL, made in German, to make the solid-liquid separation, and remove the extraction of solid waste.

Next, there are three steps of OsrHSA purification. The main types of equipment are 8 materials tanks in a row and 5 sets of chromatography systems. Each chromatographic system is consists of one AKTA Process control system and one AxiChrom chromatography column, the diameter of the column is 1 meter, which is the most advanced product from GE healthcare, made in Sweden.

Fully Automatic Online Operation

![]()

AxiChrom Chromatography Column with 1-meter diameter

![]()

10 Tons of Extraction Tanks

![]()

Downstream Process Development and OEM

Healthgen Biotech, specializing in molecular pharmaceutical research and development, is focusing on developing and manufacturing a series of animal-free and safe products by using the State-of-the-Art platform called OryzHiExp, having a high capacity to express proteins or small peptides in the rice grain. Using the OryzHiExp platform, Healthgen Biotech can provide customized protein or peptides expression and purification services. The process route and infrastructure of large-scale protein purification have been established and can implement the industrial expression and production requirements.

Healthgen Biotech has a strong technical force, advanced and complete protein expression and purification technology research, and large-scale production facilities can provide high capacity and significant advantages alternative development and manufacturing approaches.

Provide expression service of proteins of 100-1000 amino acid molecular mass and polypeptides of fewer than 100 amino acids for customers.

Establish and optimize and cost-effective extraction and purification process protocol

Developing analytic methodology method and methodology validation

Advantages Provided by Healthgen Biotech

| Phase | Service |

|

Phase 1: Generation of genetic engineering plants |

Gene optimization and synthesis, vector construction |

| Generation of transgenic plants (T0, 20~50 positive plants) | |

| Screening for high expression lines | |

| Phase 2: Lab-scale | Screening the genetic stability of homozygous genetic engineering lines |

| Detection and activity analysis of recombinant protein | |

| Developing a protocol for purification of the protein and providing a microgram scale with 90-95% purity | |

| Phase 3: Pilot-scale | Providing the milligram or gram protein with 90%~95% purity |

| Phase4: Large scale | Developing a protocol of large processing and manufacturing |

The R&D center, 200 square meters, has AKTA purification systems from GE, tangential flow filter from Millipore, microplate reader from MD Versamx, Nanovue plus ultra microspectrophotometer from GE, 5810R refrigerated centrifuge from Eppendorf, Micro Pulser Electroporator from BioRad, Syngene gel imaging system, RU water purification system from Millipore and so on.

![]()

Healthgen has 5 sets of AKTA protein purification systems from GE, which are equipped with different specifications of low-pressure columns, such as Tricon 5/20, XK 16/20, XK 16/40, XK 26/20, XK26/40, XK50/20, XK50/30, to meet various demands of protein purification process development.

![]()

The rice calli are cultured in the illumination culture chamber at constant temperature. Healthgen can produce 150,000 strains of transgenic rice calli per year, and complete at least 15 genes transformation per year.

![]()

Contact Person: Miss. Vicky Wu

Tel: +86-15201040528

Fax: 86-27-59403933-59416006